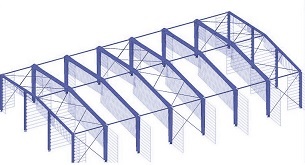

PEB DESIGN

- Structural Analysis & Design of Steel Buildings.

- Design of Steel Connections.

- Preparation of Detailed Calculation Reports.

- Preparation of Detailed Approval Drawings

- Estimation of Steel Quantity

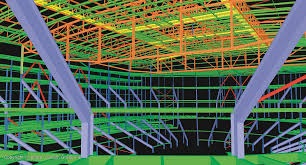

PEB DETAILING

- Anchor Bolt Plan(For Construction)

- Erection Drawings(For Construction)

- Shop Sketches(For Production)

- Bill of Materials (For Production and Shipment)

Structural Analysis & Design of Steel Buildings. –Structural Analysis and Design of steel building will be done using latest softwares (STAAD).We adapt all the latest design codes and practices of Pre-Engineered Building industry. During the process of thorough analysis and design, we will uncover any discrepancies, missing information or contradictory information that may require further clarification.

If this occurs, a questionnaire will be submitted to you. Prompt response from you for such technical clarification will minimize delays in engineering design.

Design of Steel Connections:- Connection design will be done using the latest software (RAM).Steel sections are manufactured and shipped to some standard lengths, as governed by rolling, transportation and handling restrictions. Connections are structural elements used for joining different members of a frame work. Unless properly designed, the connections joining the members may be weaker than the members being joined.

It is desirable to avoid connection failure before member failure for the following reasons:

- To achieve an economical design, usually it is important that the connections develop the full strength of the members.

- Usually connection failure is not as ductile as that of steel member failure

Therefore, design of connections is an integral and important part of design of steel structures. They are also critical components of steel structures, since

- They have the potential for greater variability in behaviour and strength

- They are more complex to design than members

- They are usually the most vulnerable components, failure of which may lead to the failure of the whole structure.

Thus designing for adequacy in strength, stiffness and ductility of connections will ensure deflection control during service load and larger deflection and ductile failure under overload. Hence, a good understanding of the behaviour and design of joints and connections in steel structures is an important task.

Preparation of Detailed Calculation Reports:-

Detailed Design Calculation will be presented to the client, after the completion of Design and Analysis of the Structure. The Calculation sheets will include all the design parameters considered and also output files of Analysis done with the help of software. The calculation report will also include the Design sketches, Drainage and Bracing calculations.

Preparation of Detailed Approval Drawings:-

Approval drawings will be prepared by Competent Detailing Engineers and these drawings will be sent to the Client prior to the preparation of final Detailing Drawings. Approval Drawings will show in detail, the layout and Anchor bolt plan of the building. Also other relevant drawings like, Plans, Elevations, Cladding Details, Material specifications, Cross sections, Other substructures and accessories considered in the building will be clearly shown. The client should closely check and verify all the Approval drawings and notify any discrepancies found in the drawings at this stage. The drawings should be checked for all kind of discrepancies like access obstruction, utility provisions, Municipality or local administration rules and regulations, Material fitness for environmental conditions, Transportation limitation to the site etc..

Estimation of Steel Quantity:-

An estimation sheet will be provided to the client with the weights of elements considered in the building. The estimate will include split up of weights in different categories for the Steel part of the building under the scope of consideration of Pebbers Structures. Only tonnage of steel elements of the structure will be provided in the estimate. Any alteration or addition in Architectural, Physical, Design, Loading, accessory or other elements of the building will result in expiration of the estimate provided. In that case a new revised estimate will be issued including the new alterations or additions.

Anchor Bolt Plan (For Construction):-

Anchor bolt plans are submitted after all technical matters are finalized. They are “Issued For Construction” drawings and are intended to enable the customer to proceed with civil work foundations in preparation for the delivery of the pre-engineered steel building. Anchor bolt plans are put in erection drawings

Anchor bolt plans contain :

- Size and quantity of anchor bolts and their exact location.

- Dimensions of all column bases.

- Column reactions for all main and secondary columns.

- Door (sliding, roll up, personnel, etc.) fixing details.

- Recommended drainage outlet locations.

During the execution of civil works, anchor bolt plans must be fully complied with to avoid fitting problems during erection.

Erection Drawings(For Construction):-

Erection drawings are final “Issued For Construction” drawings. They show the installed locations of every component of a building. Erection drawings identify the part marks (usually factory stamped on the steel members) of all the components of the pre-engineered building. Like anchor bolts plans, erection drawings must be followed precisely by the erector in order to result in a quality building.

Shop Sketches(For Production):-

Dimensions, manufacturing conventions, and special fabrication instructions should be included on the shop drawing. It should be clear to fabrication personnel what will be manufactured from the shop drawings alone.

Bill of Materials:-

This is a list of all the components used in a building and their respective quantities. It is used to verify the quantities received in the delivery packing lists and corresponds to the quantities shown on the erection drawings.